A unit consisting of multiple containers of canine sustenance, consolidated and secured for efficient storage and transport, typically resting upon a standardized platform structure. This facilitates movement via mechanized equipment, optimizing logistical processes.

Such consolidated units offer significant advantages in bulk purchasing, inventory management, and reduced handling costs for retailers and large-scale consumers. Historically, the adoption of this method reflects an evolution in supply chain efficiency, minimizing the time and labor associated with individual package handling.

The following sections will elaborate on the considerations for sourcing these units, assessing product quality within them, and optimizing storage solutions to maintain the integrity and freshness of the contained product.

Procuring Palletized Canine Sustenance

Efficient acquisition of substantial quantities of canine sustenance necessitates careful consideration of several factors to ensure optimal value and suitability for the intended purpose.

Tip 1: Supplier Vetting. Prioritize establishing relationships with reputable suppliers known for consistent product quality and adherence to stringent food safety standards. Request documentation pertaining to manufacturing processes and ingredient sourcing.

Tip 2: Volume Assessment. Accurately determine the required volume based on consumption rates and storage capacity. Avoid overstocking, which can lead to product degradation and potential waste.

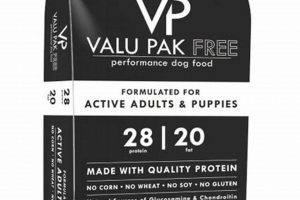

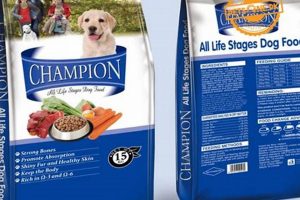

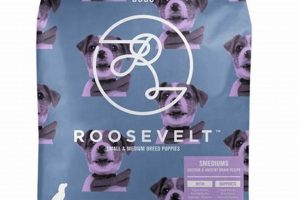

Tip 3: Formulation Review. Scrutinize the nutritional composition of the contained product. Verify that the formulation meets the specific dietary needs of the target canine population, considering factors such as age, breed, and activity level.

Tip 4: Cost Analysis. Conduct a comprehensive cost analysis, factoring in not only the per-unit price but also transportation expenses, storage costs, and potential discounts for bulk purchases.

Tip 5: Pallet Integrity. Upon delivery, meticulously inspect the integrity of the structure. Ensure that the wrapping is intact, and there are no signs of damage or tampering. Reject any compromised loads.

Tip 6: Batch Coding Verification. Verify that all individual units within the consolidated structure possess consistent and legible batch codes. This facilitates traceability in the event of a product recall or quality control issue.

Tip 7: Storage Environment. Implement a storage protocol that maintains a consistent temperature and humidity level. Protect the contents from direct sunlight and pest infestations to prevent spoilage.

By adhering to these guidelines, organizations can optimize the procurement process, minimize risks associated with spoilage or contamination, and ensure a consistent supply of high-quality nutrition for canines.

The subsequent sections will address advanced storage strategies and quality assurance protocols for sustained management of bulk canine sustenance.

1. Cost-effectiveness

Procuring canine sustenance in consolidated palletized units presents inherent cost-saving opportunities relative to individual bag purchases. These savings stem from several interconnected facets.

- Volume Discounting

Bulk purchasing arrangements frequently yield per-unit price reductions. Suppliers often offer tiered pricing structures where larger order quantities trigger increasingly favorable rates. This directly reduces the overall expenditure on canine nutrition.

- Reduced Transportation Costs

Consolidating multiple units onto a single pallet optimizes transportation efficiency. Shipping a single pallet incurs lower transportation expenses compared to shipping the equivalent number of individual bags separately. This translates into decreased logistical expenditures.

- Minimized Handling Labor

Palletized deliveries significantly reduce manual handling requirements. Mechanized equipment, such as forklifts, can efficiently move entire units, minimizing labor costs associated with unloading, storage, and inventory management.

- Decreased Packaging Waste

While individual units still require packaging, purchasing in bulk reduces the overall volume of packaging materials per unit of product. This not only lowers waste disposal costs but also aligns with sustainability initiatives, potentially generating positive public relations.

The combined effect of volume discounting, reduced transportation costs, minimized handling labor, and decreased packaging waste contributes to a substantial improvement in the overall cost-effectiveness of acquiring canine sustenance in palletized form. This translates into significant financial benefits for organizations responsible for feeding large populations of canines.

2. Storage Optimization

Effective storage optimization is paramount when managing substantial quantities of canine sustenance, particularly when acquired in palletized units. Improper storage can lead to product degradation, spoilage, and potential financial losses. Strategic planning and implementation are essential to maintaining product integrity and maximizing shelf life.

- Vertical Space Utilization

Maximizing vertical space within a storage facility is crucial for efficiently accommodating palletized units. Implementing racking systems allows for the safe stacking of pallets, significantly increasing storage capacity without expanding the facility’s footprint. Proper racking design must account for pallet weight and dimensions to ensure structural integrity and prevent collapses. In warehouses, this approach can double or triple usable storage space.

- Environmental Control

Maintaining a stable and controlled environment is essential for preserving product quality. Temperature fluctuations, humidity, and direct sunlight can accelerate spoilage and degrade the nutritional value. Climate-controlled storage facilities are recommended, particularly in regions with extreme weather conditions. Monitoring systems should be implemented to track temperature and humidity levels, allowing for timely intervention to prevent adverse conditions.

- Pest Management

Palletized units of canine sustenance are susceptible to pest infestations. Implementing a comprehensive pest management program is critical to preventing contamination and product loss. This includes regular inspections, preventative treatments, and the use of sealed storage areas. Proper sanitation practices, such as regular cleaning and waste removal, are also essential to minimize pest attraction.

- Rotation Strategies (FIFO/FEFO)

Implementing a systematic rotation strategy, such as First-In, First-Out (FIFO) or First-Expired, First-Out (FEFO), is crucial for minimizing spoilage and ensuring that product is consumed before its expiration date. FIFO involves utilizing the oldest stock first, while FEFO prioritizes items with the nearest expiration date. Proper labeling and inventory management systems are essential for effectively implementing these strategies.

The optimized storage of palletized canine sustenance is not merely about maximizing space; it’s about safeguarding product quality, minimizing waste, and ensuring the availability of nutritious food for the intended canine population. A holistic approach that considers space utilization, environmental control, pest management, and rotation strategies is essential for effective management and cost-efficient operations.

3. Quality preservation

Maintaining the nutritional integrity and palatability of canine sustenance acquired in bulk palletized units is paramount. The preservation of quality directly impacts canine health, well-being, and ultimately, the effectiveness of feeding programs. Several factors contribute to this critical aspect of managing resources.

- Controlled Atmosphere Packaging

Individual bags within the pallet often employ modified atmosphere packaging (MAP) techniques. These techniques manipulate the gas composition within the packaging to inhibit microbial growth and slow oxidation. Examples include reducing oxygen levels and increasing carbon dioxide or nitrogen concentrations. Improper handling or compromised packaging can negate the benefits of MAP, leading to spoilage. For example, a puncture in a bag can allow oxygen to enter, fostering mold growth and rendering the contents unsuitable for consumption. The effectiveness of MAP is crucial for extending the shelf life of products within the consolidated unit.

- Temperature Stability During Storage

Temperature fluctuations during storage can significantly impact the quality of canine sustenance. Elevated temperatures accelerate lipid oxidation, leading to rancidity and a decrease in palatability. Repeated temperature cycling can also promote moisture migration within the bags, creating conditions conducive to mold growth. Facilities with inadequate temperature control, particularly during seasonal changes, risk compromising the quality of the entire palletized unit. Maintaining a consistently cool and dry storage environment is essential for preserving the nutritional value and extending the shelf life of the product.

- Barrier Properties of Packaging Materials

The packaging materials employed in individual bags play a critical role in protecting the contents from external factors such as moisture, light, and pests. High-quality barrier films prevent the ingress of moisture, which can lead to clumping, microbial growth, and nutrient degradation. Opaque packaging protects the contents from light-induced oxidation and vitamin degradation. Damage to the packaging, such as tears or punctures, compromises these barrier properties, rendering the contents vulnerable to spoilage. The selection of robust packaging materials is therefore essential for maintaining product quality throughout the storage and distribution process.

- Protection from Physical Damage

Palletized units, despite their consolidated nature, are susceptible to physical damage during transportation and handling. Impacts, compression, and abrasion can compromise the integrity of individual bags, leading to spillage, contamination, and accelerated spoilage. Implementing proper handling procedures, such as the use of forklifts with appropriate attachments and securing the load with stretch wrap, is crucial for minimizing physical damage. Pallets themselves should be regularly inspected for structural integrity to prevent collapses that can compromise the entire unit.

The successful preservation of canine sustenance quality within a consolidated palletized unit relies on a multi-faceted approach encompassing packaging integrity, environmental control, material selection, and careful handling. Compromising any one of these factors can jeopardize the entire unit, leading to potential financial losses and negative consequences for canine health and nutrition.

4. Logistics Efficiency

The efficient movement and storage of palletized canine sustenance directly impacts cost, product integrity, and overall operational effectiveness. Optimization of logistical processes is therefore crucial for organizations handling substantial quantities of these goods.

- Streamlined Transportation

Palletization standardizes load dimensions, facilitating seamless integration with various transportation modes, including trucks, trains, and ships. This standardization reduces loading and unloading times, minimizes the risk of damage during transit, and optimizes vehicle utilization. Real-world examples include cross-docking operations where goods are transferred directly from inbound to outbound transportation with minimal storage, significantly accelerating delivery times.

- Optimized Warehouse Management Systems (WMS)

Effective WMS implementation is essential for managing palletized inventory within a warehouse environment. A WMS provides real-time visibility into stock levels, location, and expiration dates, enabling efficient order fulfillment and minimizing the risk of stockouts or spoilage. Modern WMS systems often incorporate barcode scanning and RFID technology for automated data capture, further streamlining inventory management processes. For instance, a WMS can automatically direct forklift operators to the optimal storage location for incoming pallets based on product type, expiration date, and storage capacity.

- Reduced Handling Costs

Consolidating individual units of canine sustenance onto a single pallet significantly reduces manual handling requirements. Mechanized equipment, such as forklifts and pallet jacks, can efficiently move entire pallets, minimizing labor costs associated with unloading, storage, and order picking. This reduction in manual handling also minimizes the risk of workplace injuries and reduces the potential for product damage.

- Enhanced Supply Chain Visibility

Tracking pallets throughout the supply chain provides enhanced visibility into product location and status. Utilizing technologies such as GPS tracking and electronic data interchange (EDI) enables real-time monitoring of shipments, allowing for proactive identification and resolution of potential delays or disruptions. For example, GPS tracking can alert logistics managers to deviations from the planned route, allowing them to take corrective action to minimize delivery delays.

The logistical efficiencies gained through the strategic management of palletized canine sustenance translate directly into cost savings, improved product quality, and enhanced customer service. By optimizing transportation, warehouse management, handling procedures, and supply chain visibility, organizations can effectively manage the flow of these goods from origin to point of consumption, ensuring a consistent supply of high-quality nutrition for canine populations.

5. Ingredient Integrity

Ingredient integrity, defined as the state of being unimpaired, unadulterated, and possessing the claimed nutritional profile, constitutes a fundamental element within a palletized unit of canine sustenance. The consolidated nature of these units amplifies the potential consequences of compromised ingredient integrity. A single instance of contamination or degradation within one package can, under unfavorable conditions, propagate and affect the entire pallet. Therefore, rigorous quality control measures at the point of manufacture and stringent storage protocols are not merely recommended, but essential to safeguard the nutritional value and safety of the contained product. Consider a scenario where a manufacturing defect leads to compromised packaging within several bags of a single pallet. Exposure to humidity could initiate mold growth, rendering the entire pallet unsuitable for consumption, despite the majority of bags remaining intact. This illustrates the cascading effect that compromised integrity can have within a consolidated unit.

Furthermore, maintaining ingredient integrity extends beyond preventing contamination. It encompasses preserving the nutritional value of the ingredients over time. Factors such as temperature fluctuations, exposure to light, and improper storage conditions can degrade vitamins, oxidize fats, and denature proteins, thereby diminishing the nutritional efficacy of the product. For example, prolonged exposure to high temperatures can reduce the bioavailability of essential vitamins like Vitamin E, rendering the canine sustenance less effective in supporting immune function and overall health. Understanding the interplay between environmental factors and ingredient stability is crucial for developing storage and handling protocols that minimize nutrient loss.

In conclusion, the relationship between ingredient integrity and a pallet of canine sustenance is one of critical dependence. The inherent risks associated with bulk storage necessitate a proactive approach to quality assurance, encompassing rigorous manufacturing processes, stringent packaging standards, controlled storage environments, and effective inventory management practices. Failure to prioritize ingredient integrity not only jeopardizes canine health but also carries significant economic implications due to product spoilage and potential reputational damage.

6. Inventory Control

Effective inventory control is paramount when managing palletized canine sustenance. Given the inherent nature of bulk storage, proper management prevents spoilage, reduces waste, and ensures a consistent supply of nutritionally appropriate product. Inadequate monitoring can lead to expired goods remaining in stock, creating potential health risks for canines and financial losses for the organization. For instance, a poorly managed shelter could inadvertently feed animals expired food, leading to illness and increased veterinary expenses, all stemming from deficiencies in inventory protocols.

Sophisticated inventory control systems offer several advantages. First-In, First-Out (FIFO) methodologies are crucial for managing expiration dates. Systems that automatically flag near-expiration products enable proactive measures such as discounted sales or donations to prevent losses. Precise tracking of incoming and outgoing pallets also mitigates the risk of theft or misplacement. A real-world example involves a large-scale pet food retailer employing a warehouse management system with barcode scanning. This system tracks each pallet’s location, quantity, and expiration date, minimizing errors and maximizing efficiency in order fulfillment.

In summary, the efficient control of canine sustenance inventories is crucial for operational success and canine well-being. Challenges exist, including initial setup costs and the need for trained personnel. However, the benefits stemming from reduced waste, minimized risks of spoilage, and enhanced operational efficiency overwhelmingly support the implementation of rigorous inventory control protocols for palletized canine food supplies. Proper inventory promotes responsible resource allocation, ensuring that canines consistently receive nutritionally sound sustenance.

7. Handling safety

The manual and mechanical manipulation of consolidated canine sustenance units presents inherent risks to personnel. Mitigation of these risks necessitates a comprehensive approach to handling safety, encompassing equipment operation, load management, and personnel training.

- Proper Lifting Techniques

Manual handling of individual bags within a pallet, or maneuvering smaller pallets without mechanical assistance, requires adherence to established ergonomic principles. Incorrect lifting techniques can result in musculoskeletal injuries, including back strains and sprains. Training programs should emphasize proper posture, load distribution, and the use of assistive devices when available. A distribution center that implements mandatory ergonomic training experiences a demonstrable reduction in worker compensation claims related to lifting injuries.

- Safe Operation of Mechanical Equipment

Forklifts and pallet jacks are commonly employed to move palletized loads. Operators must be adequately trained and certified in the safe operation of these machines. Regular equipment maintenance and pre-shift inspections are essential to identify and address potential mechanical failures. Speed limits within warehouse environments should be strictly enforced to prevent collisions and accidents. A company’s proactive investment in forklift safety training leads to a statistically significant decrease in equipment-related incidents.

- Load Stability and Securing Methods

Improperly stacked or unsecured pallets pose a significant safety hazard. Loads should be stable and properly secured with stretch wrap or banding to prevent shifting or collapse during transport. The weight capacity of pallets should never be exceeded, and damaged pallets should be immediately removed from service. A warehouse that meticulously inspects and reinforces pallet loads before transport minimizes the risk of product spillage and potential injuries to transportation personnel.

- Personal Protective Equipment (PPE)

Appropriate PPE, including safety shoes, gloves, and eye protection, should be worn by all personnel involved in the handling of palletized units. Safety shoes protect against foot injuries from dropped objects, while gloves provide a secure grip and prevent abrasions. Eye protection safeguards against dust and debris encountered during handling. A facility that mandates and enforces the use of PPE demonstrates a commitment to employee safety and minimizes the incidence of preventable injuries.

The integration of robust safety protocols into the handling of consolidated canine sustenance not only protects personnel from potential harm but also contributes to increased operational efficiency and reduced costs associated with workplace injuries. Prioritizing handling safety is an investment in both employee well-being and organizational success within the context of managing palletized supplies.

Frequently Asked Questions

This section addresses common inquiries regarding the acquisition, storage, and management of canine sustenance in palletized quantities. The information presented is intended to provide clarity and inform decision-making.

Question 1: What are the primary benefits of purchasing canine sustenance by the pallet?

Procuring canine sustenance in palletized units offers several advantages, including reduced per-unit cost through volume discounting, decreased transportation expenses, minimized handling labor, and enhanced inventory control capabilities.

Question 2: How should palletized canine sustenance be properly stored to prevent spoilage?

Optimal storage conditions involve maintaining a cool, dry environment with consistent temperature and humidity levels. Protection from direct sunlight and effective pest management strategies are also crucial for preserving product integrity.

Question 3: What factors should be considered when selecting a supplier for palletized canine sustenance?

Prioritize suppliers with a proven track record of consistent product quality, adherence to food safety standards, and reliable logistical capabilities. Request documentation pertaining to ingredient sourcing and manufacturing processes.

Question 4: What is the recommended method for verifying the quality of palletized canine sustenance upon delivery?

Thoroughly inspect the integrity of the pallet wrapping, ensuring that it is intact and free from signs of damage or tampering. Verify that all individual units within the pallet possess consistent and legible batch codes.

Question 5: How can inventory rotation be effectively managed when dealing with palletized canine sustenance?

Implement a First-In, First-Out (FIFO) or First-Expired, First-Out (FEFO) rotation strategy to ensure that older stock is utilized before newer stock. Maintain accurate records of expiration dates and utilize a warehouse management system for efficient tracking.

Question 6: What safety precautions should be observed when handling palletized canine sustenance?

Employ proper lifting techniques to prevent musculoskeletal injuries. Ensure that forklift operators are adequately trained and certified. Secure pallet loads with stretch wrap or banding to prevent shifting or collapse during transport. Wear appropriate personal protective equipment, including safety shoes and gloves.

The proper management of palletized canine sustenance requires careful consideration of several factors. By addressing these common questions, organizations can optimize their procurement and storage practices, ensuring a consistent supply of high-quality nutrition for canines.

The following section will discuss best practices for disposal of expired or damaged products.

Pallet of Dog Food

This exploration has underscored the complexities inherent in managing canine sustenance when acquired in consolidated palletized units. From procurement and storage to inventory control and handling safety, each facet demands meticulous attention to detail to ensure both economic efficiency and the sustained well-being of canine populations. The inherent advantages of bulk acquisition are inextricably linked to the imperative for rigorous quality assurance protocols and adherence to best practices throughout the supply chain.

Given the potential for compromised quality or safety within a pallet of dog food to have cascading consequences, stakeholders bear a responsibility to prioritize proactive measures. Continuous improvement in storage techniques, monitoring systems, and personnel training are crucial for safeguarding the integrity of canine nutrition and optimizing resource utilization. The responsible management of these resources is not merely an operational imperative; it is a reflection of a commitment to the health and welfare of the animals under care.